Thank you for Subscribing to Construction Business Review Weekly Brief

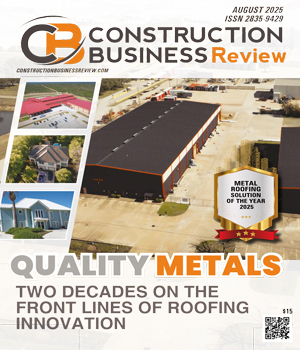

Mauricio Albo’s path into the American metal industry began with bold ambition and a deep sense of purpose. Over 35 years ago, he was handpicked by a major Mexican steel firm to spearhead its U.S. expansion. Though the initiative was short-lived, the experience left Albo with something greater than a job: a conviction. Where others saw an exit, he saw opportunity. Rather than return home, Albo stayed behind—believing he could build something better from the ground up. That belief laid the foundation for Quality Metals, launched in 2004 with little more than grit, resilience, and a commitment to doing things differently. Albo’s vision was clear: deliver unmatched quality, form lasting relationships, and solve problems the rest of the industry sidestepped. “What we’ve built at Quality Metals goes far beyond steel. It’s about setting a standard to solve problems others avoid and standing by our customers. This anniversary isn’t just a milestone—it’s a reflection of the pride we take in our craft, the trust we’ve earned, and our ongoing promise to lead with integrity,” says Albo. Foundation and Evolution of Quality Metals From its earliest days, Quality Metals has grown in lockstep with the evolving needs of the U.S. construction landscape. What began as a modest operation steadily advanced, guided by Albo’s adaptability and customer-first mindset. As regulations shifted and demand for performance increased, the company responded—expanding its capabilities, deepening its technical expertise, and strengthening its commitment to innovation. Today, with a footprint across Texas and operations in more than 11 states, Quality Metals has earned a reputation as a trusted, full-service partner in the metal building and roofing industry. Panels, Coils, Systems—Delivered with Precision Quality Metals supplies high-performance steel coils and flat sheets—available in standard and custom widths and gauges—with finishes such as Galvalume®, Kynar, SMP, and Galvanized. Its catalog also includes aluminum, copper, and stainless steel options, as well as a wide range of soffit, wall, and corrugated panels. The company’s UL Certified Standing Seam Panels (ML, NS, SL Series) are available both in-factory and via on-site forming, with over 20 panel profiles offered. Backed by a 20-year watertightness warranty, Quality Metals delivers full-package solutions, sourcing steel from top global mills and providing complete traceability, certifications, and turnkey support—from design to delivery.

Top Crawl Space Encapsulation Service 2025

The crawlspace stays out of sight and out of mind for most homeowners. Yet, these empty spaces beneath homes are ground zero for moisture buildup, mold growth, air contamination and structural deterioration. The risk is even greater in the Southeast U.S., where humidity hangs heavily in the soil and air. The rot doesn’t stop at wood and insulation; it erodes the health, comfort and efficiency of the home above it. And that’s what makes the work of companies like LiveGreen so critical. For over two decades, this NC-based, family-owned company has specialized in protecting homes from the inside out by sealing and conditioning crawlspaces with the precision, care and deep experience that only a few in the industry can offer. LiveGreen was among the earliest adopters of crawlspace encapsulation in the Triangle area long before it became a buzzword in home improvement circles. While many competitors have emerged in recent years with quick fixes or templated services, LiveGreen has built its reputation on customized, long-term solutions. The company’s services include thorough moisture assessment, removal of contaminated insulation, mold remediation and installation of foam board insulation and vapor barriers. LiveGreen also offers radon mitigation systems and handcrafted, weather-sealed access doors that provide long-term protection to the house. “Every home has its ebbs and flows, and crawlspaces are no exception,” says Matthew Blaise, operations manager. “We take the time to understand what’s going on before recommending a solution.”

Top Design and Build General Contractor Company 2025

The roots of Tampa Bay General Contractors trace back to Roberts’ early days working in the luxury neighborhoods of Beverly Hills and Bel Air, building for the likes of Sonny Bono, Marlo Thomas, and Larry Flint. That experience, coupled with his business acumen, helped shape a practical and people-focused methodology. Today, the company brings that high standard to Florida, covering everything from raw land development, commercial buildings, commercial rebuilds, and custom luxury residences. Long before the blueprints are drawn or the first shovel breaks ground, there’s a dream. Whether it’s a cozy waterfront restaurant, a striking commercial complex, or a custom luxury residence to reflect someone’s legacy, every project begins with someone’s vision. And turning that vision into reality hinges on clear, consistent communication, as bringing every stakeholder onto the same page is as essential as the plans themselves. Tampa Bay General Contractors is built around that principle. The company understands that every lasting structure starts with a shared understanding. From the earliest conversations to the final Engineer’s certification, its focus remains on collaboration, craftsmanship and delivering results that reflect each client’s unique goals. This Florida state-certified design-build General Contracting Company offers “start-to-finish solutions” for all levels of new or existing developments, be it new commercial buildings, pre-engineered steel buildings, or custom luxury residences. “We’re able to take raw land and turn it into something that becomes a buildable space. That’s what true development means to us,” says Robert Cairns, owner. “It’s not just putting up a structure but taking someone’s dream and making every piece work together to bring that vision to life.” Tampa Bay General Contractors gets involved long before the land is cleared or the paperwork is filed. When a client brings a vision, the team works to understand the full scope, guiding the process from concept to completion. Whether the land is client-owned or purchased through Tampa Bay General Contractors, the company oversees every stage—from zoning, Civil engineering, Environmental, Wetlands remediation, infrastructure, Structural Engineering, and site development, through completion. In one case, a client purchased waterfront raw land from Tampa Bay General Contractors, with the dream of opening a restaurant and townhomes. The land was untouched, overgrown and sloping toward the water. Tampa Bay General Contractors stepped in, and with careful planning, regulatory approvals and engineered infrastructure, that dream began to take shape. Today, after the required local, state, and Federal approvals, they are poised to commence on the waterfront site work and complete this client’s dream.

Garage Flooring Products Company of the Year 2025

Not too long ago, garages were mostly afterthoughts, a utilitarian space to stash away cars and Christmas lights. Fast-forward to today and that dim, dusty square footage has morphed into something much more meaningful. It’s now a workshop, a playroom, a gym, a hangout spot and, for many, a proud extension of the home. With this shift in purpose comes a new demand: the garage must now look the part. For over two decades, Swisstrax has met that need with premier modular flooring solutions for commercial, residential and industrial applications worldwide. Engineered for durability, style and ease of use, the company’s products help homeowners create environments they’re proud of. “It’s not just about the tiles or the maintenance benefits our flooring could provide. It’s about the experience we deliver, helping customers see their garage as a space of pride and purpose, where functionality and personal expression co-exist,” says Josh Nelson, vice president. The company offers a smart, elegant alternative to traditional epoxy coatings—one that holds up against the elements of nature, including rain, heat, hot tires, dirty boots and everything in between. More than that, Swisstrax helps people see the garage not as a neglected corner of the house but as a true part of their living space. Flooring that Fits Every Story Swisstrax’s product portfolio comprises a diverse range of modular flooring systems designed to last a lifetime. Ribtrax Pro, a modular tile built for durability, drainage, and easy upkeep, was the game-changer that put the company on the map. Built to handle everything from snowy salt to high desert heat, its open-profile design and underlying channeling system make cleaning as simple as hosing it down. As customer needs evolved, the Swisstrax lineup progressed in parallel, constantly innovating to stay ahead of the curve. For those spending serious time under the hood or on the floor, Ribtrax Smooth Pro was introduced, delivering the same lowmaintenance performance with a more comfortable, flat surface. The company also offers the Diamondtrax 12 series as a solid surface option. Featuring a classic diamond plate design, it’s a more economical choice for those who prefer a traditional look or are working within a tighter budget.

CXO INSIGHTS

Roof Paver Tie Down for High Winds

Davide Mangini, PNA Brand & Projects Executive, Permasteelisa North America Crop

Harnessing the Power of BIM Technology to Optimize Collaborative, Successful Projects

Tom Perry, Managing Director of Engineering Services, Shawmut Design and Construction

Construction services with a Focus on Value and Technical Proficiency

Jake Tucker, Silicon Valley Special Projects Lead, Turner Construction

The Role of Quality Control in Construction Management

Joffrion Beasley, Director of Quality Control, Chamberlin Roofing & Waterproofing

Asbestos Inside our Homes

Denio Sturzeneker, Corporate Safety Director, Plaza Construction

IN FOCUS

The Ascendant Arc of Metal Roofing in Construction

Metal roofing's popularity is rising due to its durability, energy efficiency, sustainability, and aesthetic versatility, making it a leading choice in modern construction.

Garage Spaces as Catalysts for Flooring Innovation

Garage flooring is evolving from bare concrete to diverse, advanced options like coatings, tiles, and mats, reflecting the garage's transformation into a multifunctional space.

EDITORIAL

Navigating the Changing Construction Landscape

One clear sign of this evolution is the growing adoption of integrated design-build models. By replacing fragmented handoffs with a unified process, this approach streamlines timelines, reduces costs and gives clients a single accountable team. Projects move faster, respond better to change and stay aligned with vision and budget.

Garage flooring, which was once considered a utilitarian surface is now a performance zone. Epoxy and polyaspartic coatings are engineered to resist chemicals, abrasion and heavy loads while offering quick installation and minimal upkeep. As homeowners expect more from every square foot, flooring solutions are evolving to meet higher durability, aesthetics and functionality standards.

Metal roofing is also gaining renewed interest for its durability. With extreme weather on the rise, property owners are turning to materials that offer better protection, longer life cycles and lower operating costs. Metal roofs with reflective finishes help reduce energy use and interlocking panels provide superior defense against wind, rain and fire.

Crawl space encapsulation, once an afterthought, has gained momentum as a critical component of indoor air quality and structural health. Unsealed crawl spaces harbor moisture, mold and pests—all of which can compromise insulation and degrade home environments. Today’s systems go beyond vapor barriers, using sealed liners, dehumidifiers, drainage and insulation upgrades tailored to the space. The result is a dry, controlled environment that improves energy efficiency and extends the life of HVAC and foundation systems.

Together, these changes signal a new era in construction, defined by better performance and solutions built to last.

We hope this edition of Construction Business Review helps you find the right partner for your business requirements.